Branch Hydraulic Systems won the contract to supply a hydraulic power unit to provide hydraulic power to a large earthquake simulator in India.

The hydraulic power unit was to be built and tested in our manufacturing facility in Gloucester, then dismantled and packed up to be shipped to India for re-assembly by the customer.

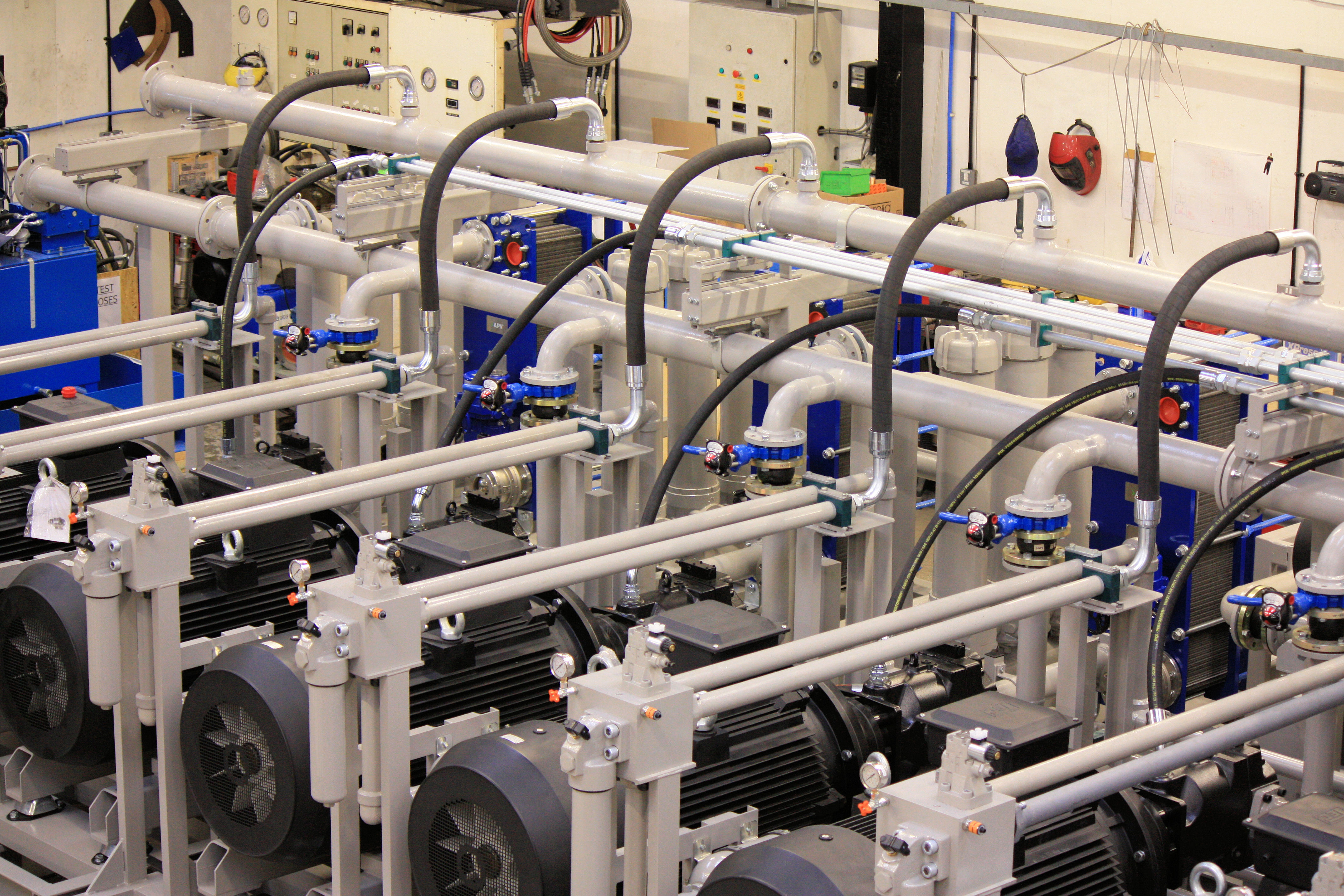

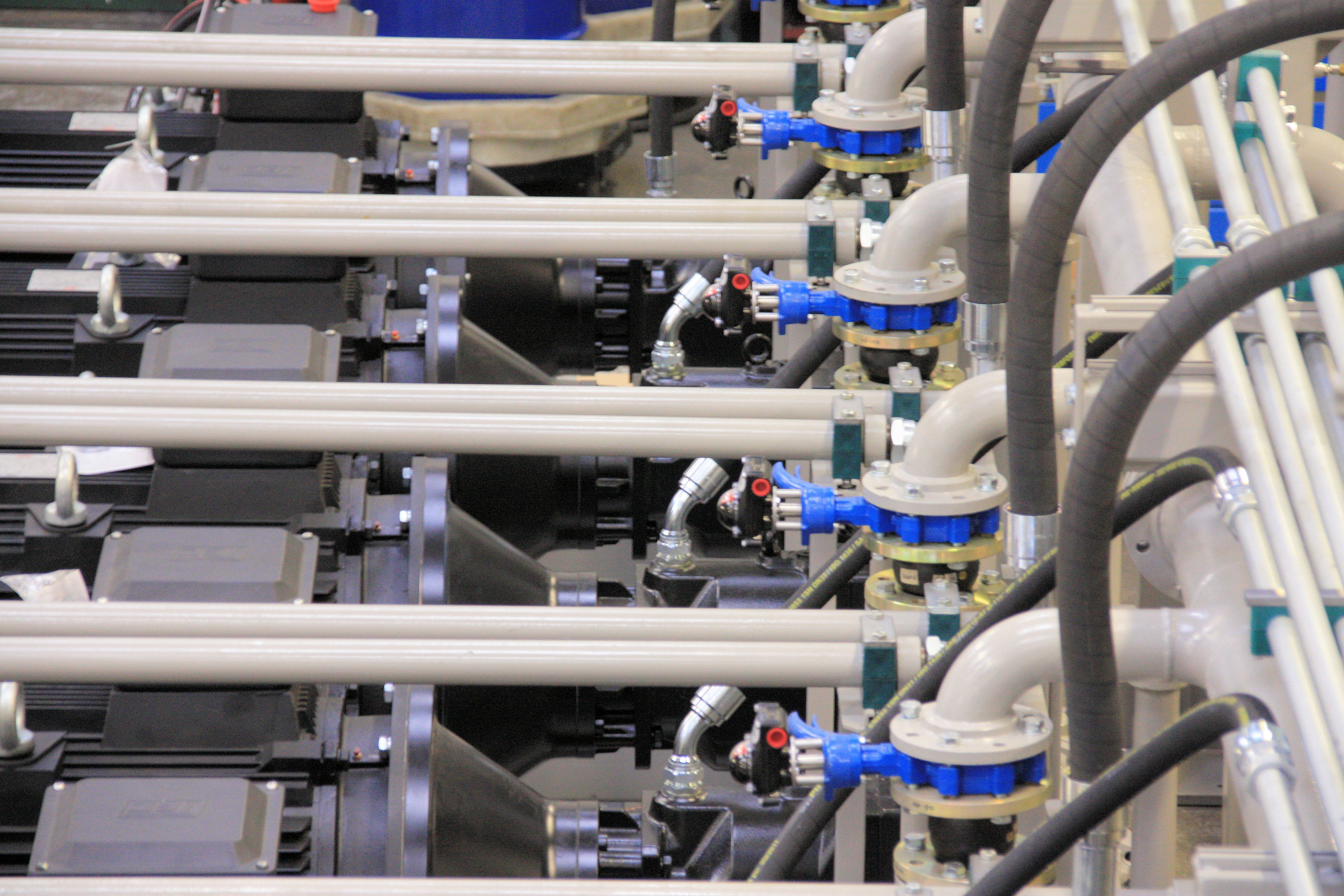

The design used nine main motor pump sets, each rated at 200KW driving a Parker PV270 axial piston pump, with facilities included on the unit for a tenth unit to be added at a later date. This gave a total capacity in excess of 3500 lpm at 280 bar. The power unit included a boost circuit to supply oil at low pressure to the main pumps, which also provided a fluid conditioning function which included filtration and 2MW of cooling capacity.

Construction of the unit was completed in Gloucester and consisted of a number of skids for various subsection including 9 main motor pump skids, reservoir assembly, boost pump assembly and 3 cooling and filtration units. Low pressure scheduled pipework and high-pressure steel pipework with all the associated brackets and clamps were manufactured, painted and fitted as part of this process.

Once the unit was completed, pipework was cleaned, flushed and pressure tested before the main components of the unit were tested. Every item was carefully labelled and packaged so as ensure a high standard of cleanliness was maintained during shipping, and to allow the unit to be re-assembled on site according to the detailed assembly drawings provided by Branch Hydraulic Systems.

If you are interested in a similar project or any hydraulic power systems, do not hesitate to contact the team today on 01452 730562 or email enquiries@grouphes.com